How Automotive Injection Molding Impacts Vehicle Design And Efficiency

Automotive injection molding is a transformative process that has significantly influenced the design, efficiency, and sustainability of modern vehicles. This manufacturing technique, which involves injecting molten plastic into a mold cavity, which has become indispensable in the automotive sector. From body panels to light housings, injection molding can produce a wide range of vehicle components that enhance both performance and aesthetics.

The Role of Injection Molding in Vehicle Design

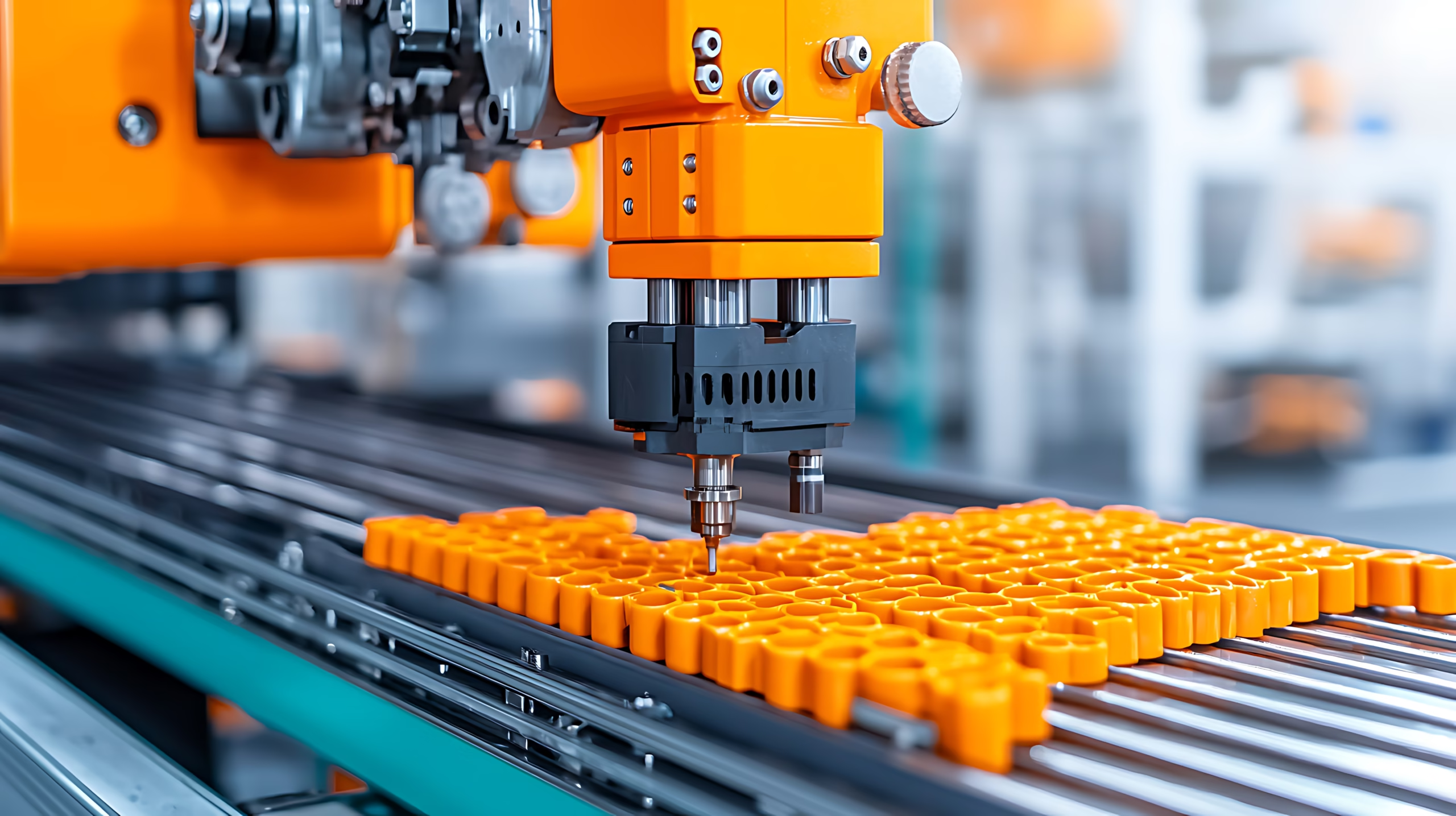

Injection molding plays a pivotal role in vehicle design by allowing automotive manufacturers to create intricate and lightweight components. The process involves heating a variety of materials, including high-performance polymers and composites, to a molten state and then injecting them into a mold cavity under high pressure. It is advantageous for producing complex geometries, such as instrument panels, sleek door handles, and aerodynamic exterior components like body panels and light housings.

Working with a reputable automotive injection molding company ensures access to advanced technology and materials. These companies often utilize thermoplastic injection molding and other types of injection molding to produce parts with superior heat resistance, chemical resistance, and strength. The precision of injection molding machines ensures that each component fits seamlessly into the vehicle’s design, minimizing air resistance and enhancing overall performance.

Enhancing Vehicle Efficiency

One of the major benefits of injection molding in the automotive industry is its contribution to fuel efficiency. By replacing heavier metal parts with lightweight plastic products, automakers can reduce the overall weight. This improves fuel economy and reduced greenhouse gas emissions. For example, injection-molded plastic components are commonly used in air intake manifolds, fuel system parts, and structural elements like bumper beams.

Moreover, injection molding enables part consolidation, where multiple functions are integrated into a single component. This approach reduces the number of separate parts needed in vehicle assembly, resulting in fewer components, lower production costs, and simplified assembly processes. For instance, a single injection-molded part might combine the functions of several metal components, leading to a more streamlined and efficient design.

Sustainability and Cost Efficiency

Injection molding aligns with the automotive industry’s push for greener manufacturing practices, including sustainable motorsport initiatives. Many injection molding companies now use recycled materials and eco-friendly resins to produce automotive plastics, reducing the environmental impact of vehicle production.

The process itself is highly efficient, generating minimal waste, with any excess material being reusable. This makes injection molding a cost-effective solution for large-scale manufacturing. The high level of automation further reduces labor costs and accelerates production speed, making it ideal for high-volume manufacturing. This scalability is particularly beneficial for the automotive sector, where demand for parts can fluctuate significantly, while still supporting sustainability goals.

Innovations in Injection Molding Technology

The automotive injection molding industry continues to evolve, driven by advancements in technology and materials. Rapid manufacturing techniques, such as 3D printing, allow for faster prototyping and more intricate designs, enabling automakers to bring new concepts to market more quickly.

Advanced technology also facilitates the integration of smart features into injection-molded components. For example, sensors and electronic elements can be embedded into plastic parts, opening up new possibilities for connected vehicles where components communicate with each other to optimize performance and safety.

Insert molding, another innovative technique, involves embedding metal or other materials into plastic components during the molding process. This enhances the strength and functionality of parts, making them suitable for demanding automotive applications. Additionally, the use of a variety of materials, including those with high impact resistance, ensures that injection-molded components can withstand the rigors of everyday use.

Quality Management and Future Prospects

Quality management is a critical aspect of automotive injection molding. Reputable companies comply with stringent quality control measures to ensure that each automotive part meets the highest standards of durability, precision, and performance.

Looking ahead, the future of automotive injection molding is bright. As the industry continues to prioritize sustainability, cost efficiency, and innovation, injection molding will remain at the forefront of vehicle design and manufacturing. Whether it’s through the development of new materials, the adoption of advanced technology, or the implementation of eco-friendly practices, injection molding will continue to drive the automotive revolution.

Enabling Customization and Aesthetic Flexibility

Injection molding is particularly beneficial for modular electric vehicle (EV) designs, where lightweight and customizable interiors are in demand. This technology integrates seamlessly with advanced infotainment or autonomous driving systems, ensuring vehicles are future-ready. The process enhances both aesthetic appeal and functionality, meeting diverse consumer preferences while maintaining durability and adaptability.

Bottom Line

Automotive injection molding is a cornerstone of modern vehicle design and manufacturing. Its ability to produce lightweight, durable, and complex components has a profound impact on vehicle efficiency, aesthetics, and sustainability. From reducing weight and enhancing functionality to supporting eco-friendly practices and enabling rapid manufacturing, injection molding is at the heart of the automotive industry’s evolution.